We understand that equipment downtime is more than just a headache.

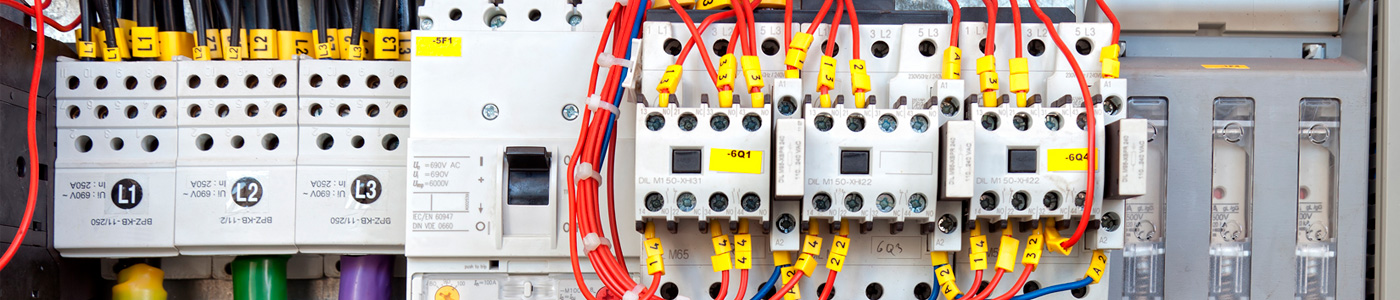

The maintenance of any electrical system is often overlooked. Once a new system is up and running, no one gives much thought to its continued smooth operation — until something goes wrong. Unmaintained electrical equipment has a greater potential to fail, causing injuries to your employees, damage to your property, and costly downtime. Performing consistent and proper maintenance on electrical systems allows you to thwart potential hazards.

We offer maintenance services that comply with industry standards and government regulations and that are tailored specifically to the needs of your facility and schedule, ensuring maintenance tasks minimize impact on your active facility. Even if you’re unsure when your facility was last serviced, trust CES to do a thorough check and determine a future schedule that works for your equipment and your budget.